|

|

Feellan Technology |

|

Tel: |

+86 755-89312189 |

|

E-mail: |

market@feellan.com |

|

Web: |

www.feellan.com |

|

Add: |

Unit 205, B3 Bldg., Shun Jing Pioneer Park, Long Teng 3rd Road, Long Gang Central City, Shenzhen 518172 |

|

|

|

|

|

| Effluent color monitoring for water treatment |

Home > Technical > Effluent color monitoring for water treatment |

|

|

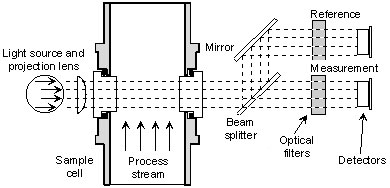

In order to meet environmental discharge requirements, it is becoming more and more necessary to measure the color of plant effluent and determine the amount of dissolved color and solids within it. The normal practice in many plants is to manually take effluent samples hourly and perform lab color measurements to insure conformity to discharge limits, often comparing the samples to APHA, HAZEN or similar color standards. The Model 682 colorimeter can be used to monitor effluent color on-line. It utilizes a dual beam measurement method that measures and computes the ratio of two light beams, reference and measurement. A light source shines visible light through the effluent stream via two transparent windows and some projection optics. Opposite the light source, the light received is split into two separate beams and their intensity measured. In the case of APHA and Hazen color measurement, the reference channel is filtered at 750nm and the measurement channel at 420nm, but the two channels can be almost any two wavelengths.

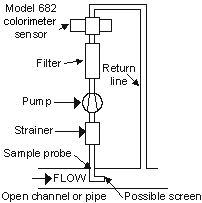

Using an in-line monitor such as a Model 682 colorimeter, expensive sampling and analysis can be avoided and alarm functions can be used to alert an operator of excessive levels of contaminant before discharge, avoiding potential penalties and fines from local authorities. A typical installation uses a Model AF21 or Model AF22 dual beam absorbance sensor in a sample stream with the transmitter housed locally in a NEMA 4 enclosure. A sample probe with a screen to reject large debris is used to extract the sample from a larger discharge pipe. A self-priming pump, capable of delivering about ½ liter of liquid per minute draws the sample through the loop. The strainer should be installed to keep larger particles from getting to the pump. After the pump, a 10 micron cartridge filter cleans the sample prior to entering the sensor. The 10 micron filter approximates a typical laboratory procedure and ensures correlation to lab samples is direct, making the calibration of the system easier. Flow should be vertically up through the sensor, ensuring the sample cell is filled at all times. Valves should be fitted to allow isolation of the loop for calibration and maintenance purposes.

Typical installation

Calibration of the Model 682 is carried out by filling the sensor sample cell with known, laboratory tested color examples. The Model 682 reads out directly in APHA/HAZEN units and when combined with a correctly configured sensor, can be spanned for a wide range of color measurement. A reference filter, installed into the sensor housing is used to check calibration periodically. With proper maintenance, the instrument should not require recalibration using liquid standards. The instrument has a 4 to 20mA output relating to the calibrated span. An alarm can be set to operate when the measured color exceeds the desired maximum color value. Both of these outputs can be used as inputs into an overall control scheme for effluent color management. The use of a MODEL 682 in this application eliminates the need for operator sampling and conducting laboratory spectrophotometer measurements, both of which are time consuming and costly. The process stream is continuously monitored and can be logged to provide a record for regulatory agencies. For further information on the Model 682 colorimeter and Model AF21/AF22 dual beam absorbance sensors, please contact your local Wedgewood Analytical sales representative or Wedgewood Analytical direct.

The use of a Model 682 in this application eliminates the need for operator sampling and conducting laboratory spectrophotometer measurements, both of which are time consuming and costly. The process stream is continuously monitored and can be logged to provide a record for regulatory agencies.

|

|